Server-Online

400-1133-638

13925536251

Tableware Vacuum Coating Machine

Knife and fork vacuum coating machine

Hardware vacuum coating machine

Bowl Vacuum Coating Machine

Magnetron sputtering coating machine

Sputtering ion coating machine

Arc ion coating machine

Intermediate frequency ion coating machine

Knife and fork environmental protection coating equipment

Tableware Vacuum Plating Equipment

Hardware environmental protection electroplating equipment

Bowl PVD coating equipment

Tableware vacuum coating equipment

Kitchenware food grade electroplating equipment

Kitchenware Food Grade Coating Equipment

Kitchenware Food Grade Vacuum Coating Equipment-PVD Ion Coating Machine

Kitchenware / Tableware - Special Coating Equipment - Multi-arc Ion Coating Machine

Kitchenware / Tableware - The special coating equipment is mainly configured as a cathodic arc ion source. Its process is simple and environmentally friendly, and there is no three-waste discharge, which meets the national environmental protection standards. It can be used for decorative plating of stainless steel knives, forks, spoons, pots, tableware, dishes and other kitchen utensils.

The principle of multi-arc ion coating of tableware coating equipment (cathode arc) is based on cold cathode self-sustained arc discharge plasma evaporation and ionization of plating materials, combined with pulse bias technology to improve the energy and activity of deposited particles and enhance the various properties of the film layer. It can be coated not only on the surface of metal products but also on the surface of non-metal products; it can be coated with metal film, titanium nitride, titanium carbide, zirconium nitride, chromium nitride and nickel, chromium, copper and other compound films Layer superhard film, multi-component film, titanium nitride doped gold film, etc. can also be plated.

Kitchenware arc ion coating equipment is an efficient and pollution-free ion coating equipment, which has the advantages of fast deposition speed, high ionization rate, large ion energy, simple equipment operation, low cost and large production capacity.

The color can be plated with gold, rose gold, champagne gold, gun black, blue, colorful, silver, etc. Various patterns can be obtained by applying water-soluble paint blocking technology.

Device parameters:

|

Application industries: kitchen utensils, tableware, electronics, machinery, aviation, automobiles, watches, decoration, hardware, bathroom equipment, construction hardware. |

||||||||

|

Coating layer: gold, silver, nickel, titanium nitride, titanium carbide, zirconium nitride, chromium nitride, black chromium, colored oxide, |

||||||||

|

Features: Computer touch screen operation, fully automatic operation, stable performance, and finer film layer. |

||||||||

|

DY-MS series: Vacuum multi-arc ion coating machine model and technical parameters |

||||||||

|

model |

DY-MS-700 |

DY-MS-900 |

DY-MS-1000 |

DY-MS-1250 |

DY-MS-1400 |

DY-MS-1600 |

||

|

Coating chamber size |

Ф700×H900mm |

Ф900×H1100mm |

Ф1000×H1200mm |

Ф1250×H1350mm |

Ф1400×H1600mm |

Ф1600×H1800mm |

||

|

power type |

Arc power supply, filament power supply, pulse bias power supply |

|||||||

|

Vacuum chamber structure |

Vertical front door structure, rear air extraction system, double-layer water-cooled chamber |

|||||||

|

Vacuum chamber material |

High-quality stainless steel cavity |

|||||||

|

Ultimate vacuum |

6.0×10-4Pa |

|||||||

|

Pumping time (no load) |

Pumping from the atmosphere to 8.0×10-3Pa≤12 minutes |

|||||||

|

Vacuum acquisition system |

Diffusion pump or molecular pump + Roots pump + mechanical pump + maintenance pump (specific models can be configured according to customer requirements) |

|||||||

|

Number of arc sources |

4 or 6 |

6 or 8 |

8 or 10 |

10 or 12 |

14 or 16 |

16 or 18 |

||

|

Bias supply |

10KW/a set of |

20KW/a set of |

20KW/a set of |

30KW/a set of |

40KW/a set of |

50KW/a set of |

||

|

Workpiece turret |

Planetary rotation, frequency conversion speed regulation (controllable and adjustable) |

|||||||

|

Rotation method |

||||||||

|

Work piece baking temperature |

Controllable and adjustable from room temperature to 450°C (PID temperature control) |

|||||||

|

process gas |

3-way or 4-way process gas flow control and display system optional automatic gas filling system |

|||||||

|

cooling method |

The water circulation cooling method requires a cooling water tower or an industrial chiller or a cryogenic system. (customer provided) |

|||||||

|

control method |

Manual/automatic integration mode, touch screen operation, PLC or computer control |

|||||||

|

Total power of the whole machine |

25KW |

30KW |

35KW |

45KW |

60KW |

75KW |

||

|

Alarm and Protection |

Alarm for abnormal conditions such as water shortage, over-current and over-voltage, open circuit, etc. of pumps and targets, and implement corresponding protection measures and electrical interlock functions. |

|||||||

|

Equipment footprint |

W2m×L3m |

W2.5m×L3.5m |

W3m×L4m |

W4m×L5m |

W4.5m×L6m |

W5m×L7m |

||

|

Other technical parameters |

Water pressure ≥ 0.2MPa, water temperature ≤ 25 ℃, air pressure 0.5-0.8MPa |

|||||||

|

Remark |

The specific configuration of the coating equipment can be designed according to the customer's coating product process requirements. |

|||||||

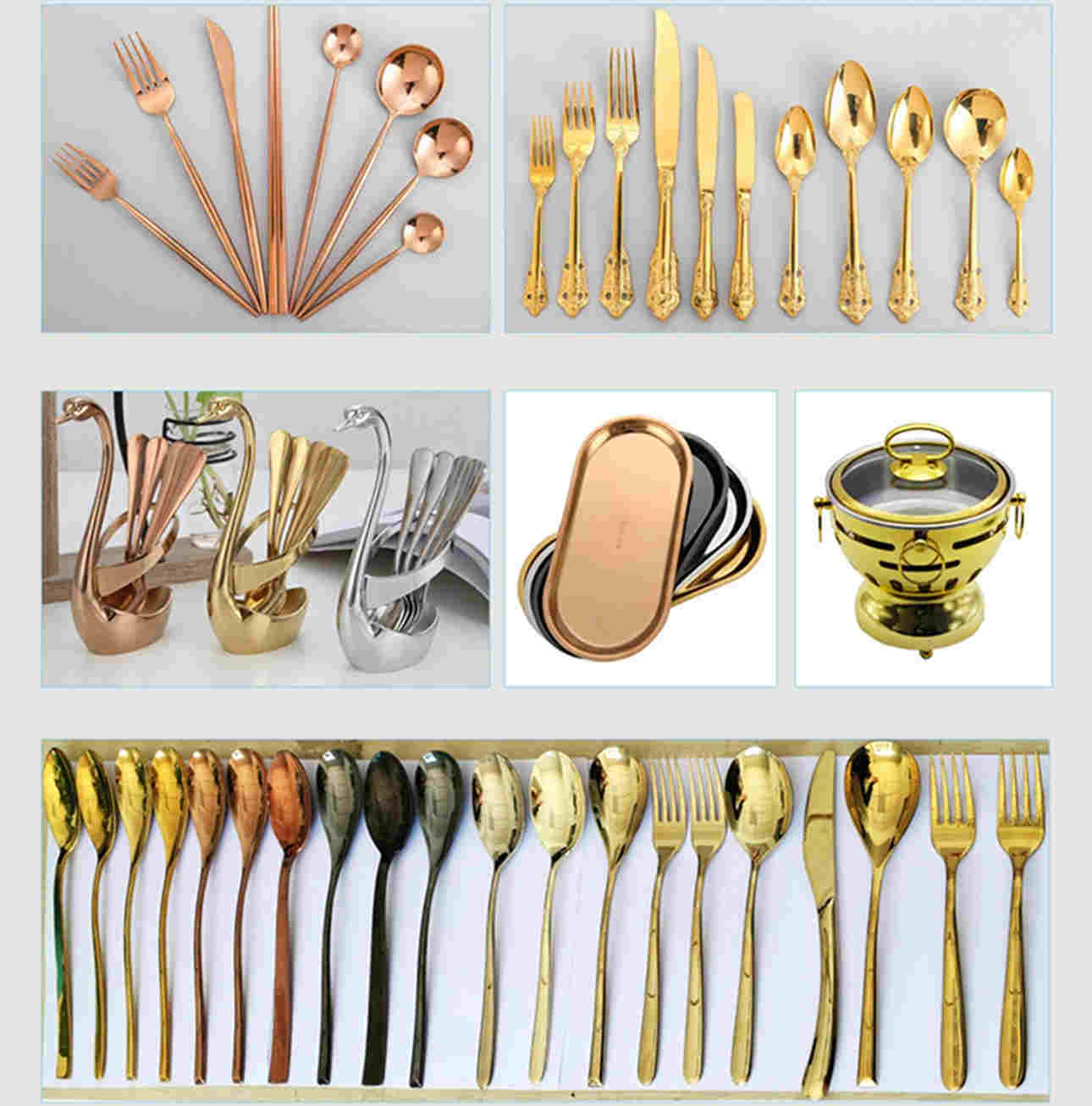

Sample display:

Dingyi Technology

The company can design various specifications and models of vacuum coating machines according to user requirements.

The vacuum unit and electronic control system can also be designed and configured according to user requirements.

Dingyi provides world-leading coating application solutions: providing system services such as equipment, materials, processing, technology, and project support.

Dingyi vacuum coating equipment includes: evaporation coating machine, magnetron sputtering coating machine, magnetron evaporation dual-purpose coating machine, multi-arc ion coating machine, intermediate frequency ion coating machine, AF coating machine, super hard coating coating machine, PVD Coating line, PVD coating project supporting assembly.

PVD process technology uses vacuum conditions to deposit various metal and non-metal films on the surface of plastic parts by means of distillation or sputtering.

Dingyi Technology matches the best coating process scheme according to the characteristics of the product.

The advantages and characteristics of Dingyi vacuum coating machinery and equipment in the industry: professionalism, integrity and reliability.

300 meters southwest of Jindu Police Station, Century Avenue, Jindu Town, Gaoyao District, Zhaoqing City, Guangdong Province, China

+86 400-1133-638

+86 13925536251 (Mr. Deng)

380236471@qq.com

Copyright © 2022 Zhaoqing Dingyi Technology Co., Ltd