Server-Online

400-1133-638

13925536251

To enter a new industry, you need to start with the most basic knowledge, and gradually study in depth. The same is true in the PVD vacuum coating equipment industry. It is necessary to start from the basic knowledge of PVD vacuum coating equipment. For example, the coating equipment structure, principle, technology, post-machine maintenance, and the overall effect of the final product coating, all need to be done step by step.

Dingyi Technology introduces five basic knowledge of PVD vacuum coating machine coating industry in detail.

1. PVD (Physical Vapor Deposition) technology is mainly divided into three categories, vacuum evaporation coating, vacuum sputtering coating and vacuum ion coating. Compared with the three classifications of PVD technology, the corresponding vacuum coating equipment also includes vacuum evaporation coating machine, vacuum sputtering coating machine and vacuum ion coating machine. In the past ten years, the development of vacuum ion plating technology is the fastest, and it has become one of the most advanced surface treatment methods in the contemporary era. What we usually call PVD coating refers to vacuum ion coating; what we usually call PVD coating machine refers to vacuum ion coating machine

2. Ion coating equipment (PVD coating) technology, its principle is to use low voltage and high current arc discharge technology under vacuum conditions, use gas discharge to evaporate the target material and ionize the evaporated material, under the action of the electric field, The evaporated substance or its reaction product is deposited on the workpiece. The same point between PVD coating and traditional chemical electroplating is that both belong to the category of surface treatment, and both of them cover the surface of one material on the surface of another material in a certain way. The difference between the two is: the bonding force between the PVD coating film and the surface of the workpiece is greater, the hardness of the film layer is higher, the wear resistance and corrosion resistance are better, and the performance of the film layer is more stable; PVD coating can be coated The types of film layers are more extensive, and the colors of various film layers that can be plated are also more and more beautiful; PVD coating will not produce toxic or polluting substances.

3. At this stage, PVD coating cannot replace chemical electroplating, and in addition to direct PVD coating on the surface of stainless steel materials, before PVD coating is performed on workpieces of many other materials (such as zinc alloy, copper, iron, etc.), They all need to be electroless Cr (chromium) plated first. PVD coating is mainly used on some relatively high-end hardware products, and those hardware products with lower prices are usually only electroplated without PVD coating. The film layer plated by PVD coating technology has the characteristics of high hardness, high wear resistance (low friction coefficient), good corrosion resistance and chemical stability, etc., and the life of the film layer is longer; at the same time, the film layer can be greatly Improve the appearance and decoration performance of the workpiece.

4. The PVD film layer can be directly plated on stainless steel and hard alloy. For die castings such as zinc alloy, copper, and iron, electroless chrome plating should be carried out first, and then PVD plating is suitable. PVD coating technology is an environmentally friendly surface treatment method that can truly obtain micron-scale coatings without pollution. It can prepare various single metal films (such as aluminum, titanium, zirconium, chromium, etc.), nitride films (TiN [titanium gold ], ZrN [zirconium gold], CrN, TiAlN) and carbide films (TiC, TiCN), and oxide films (such as TiO, etc.). The thickness of the PVD coating film layer is micron-level, and the thickness is relatively thin, generally 0.1 μm to 5 μm. The thickness of the decorative coating film layer is generally 0.1 μm to 1 μm, so the surface of the workpiece can be improved without affecting the original size of the workpiece. Various physical and chemical properties, and can maintain the size of the workpiece basically unchanged, no further processing is required after plating.

5. The application of PVD coating technology is mainly divided into two categories: decorative plating and tool plating. The purpose of decorative plating is mainly to improve the appearance, decorative performance and color of the workpiece while making the workpiece more wear-resistant and corrosion-resistant to prolong its service life; this aspect is mainly used in various fields of the hardware industry, such as door and window hardware, locks, bathroom hardware and other industries. The purpose of tool plating is mainly to improve the surface hardness and wear resistance of the workpiece, reduce the friction coefficient of the surface, and improve the service life of the workpiece; this aspect is mainly used in various knives, scissors, turning tools (such as turning tools, planers, milling , drill bits, etc.) and other products

The basic knowledge of PVD vacuum coating equipment is not limited to the above five items, such as optics, decoration, winding, hard coating, etc., according to the type. The types are different, and the relevant equipment knowledge is also different.

What is the difference before and after the workpiece is plated by the vacuum coating machine?

2023-03-11

What is the difference before and after the workpiece is plated by the vacuum coating machine?

2023-03-11

Vacuum coating machines are widely used in various industries, including machinery, electronics, hardware, aerospace, medical, chemical and other fields.

Vacuum coating machine design should pay attention to details

2023-03-03

Vacuum coating machine design should pay attention to details

2023-03-03

In order to ensure that the vacuum coating machine has good sealing performance, it is necessary to cut off the cause of possible leaks at the source

How to check for leaks during installation and commissioning of vacuum coating machine

2023-03-03

How to check for leaks during installation and commissioning of vacuum coating machine

2023-03-03

The leak detection link of the vacuum coating machine is a step that needs to be carried out in all links from design, manufacture, commissioning, use, etc., and it is absolutely necessary.

Vacuum coating machine sputtering sputtering process introduction

2023-03-03

Vacuum coating machine sputtering sputtering process introduction

2023-03-03

The sputtering method can be used to prepare material films with high melting point and low vapor pressure that cannot be prepared by the evaporation process, which is convenient for the preparation of thin films of compounds or alloys. The vacuum coating machine sputtering sputtering process is mainly used for sputtering etching and film deposition. .

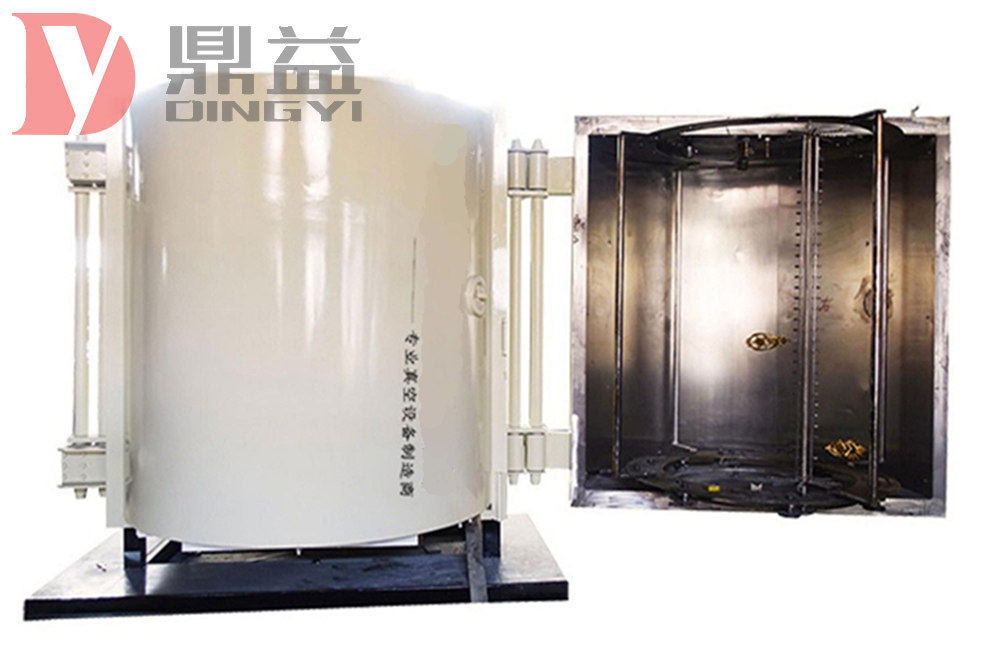

Vertical double-door-high vacuum evaporation coating machine

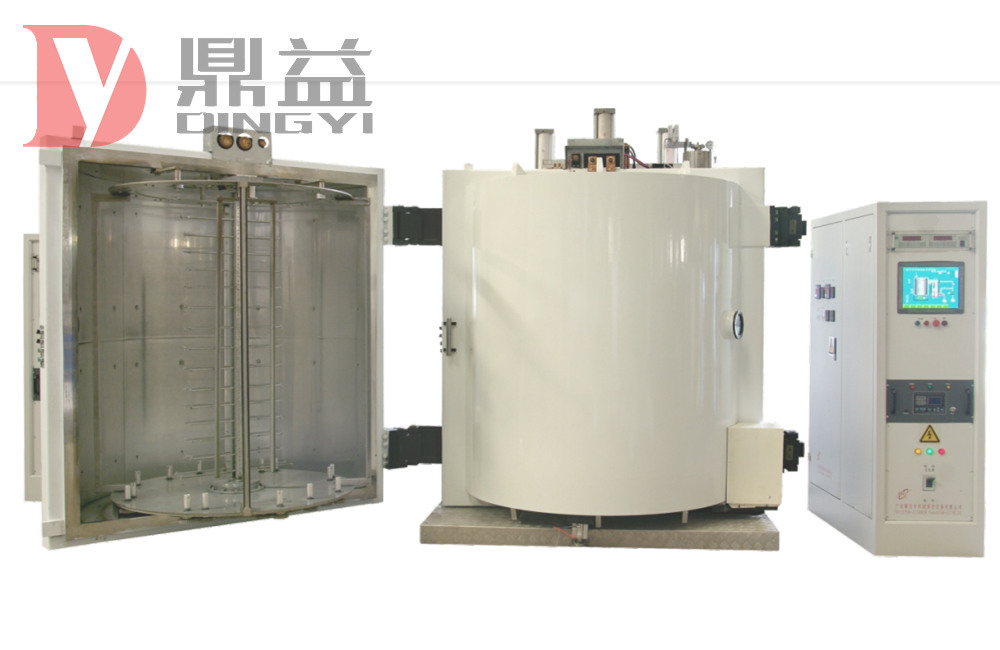

Horizontal evaporation coating machine

Vacuum coating machine for lamps

AF anti-fingerprint coating machine

PVD aluminum mirror coating machine

Vacuum internal plating equipment - evaporation coating machine - plastic/glass lampshade

Magnetic control evaporation dual-purpose coating machine

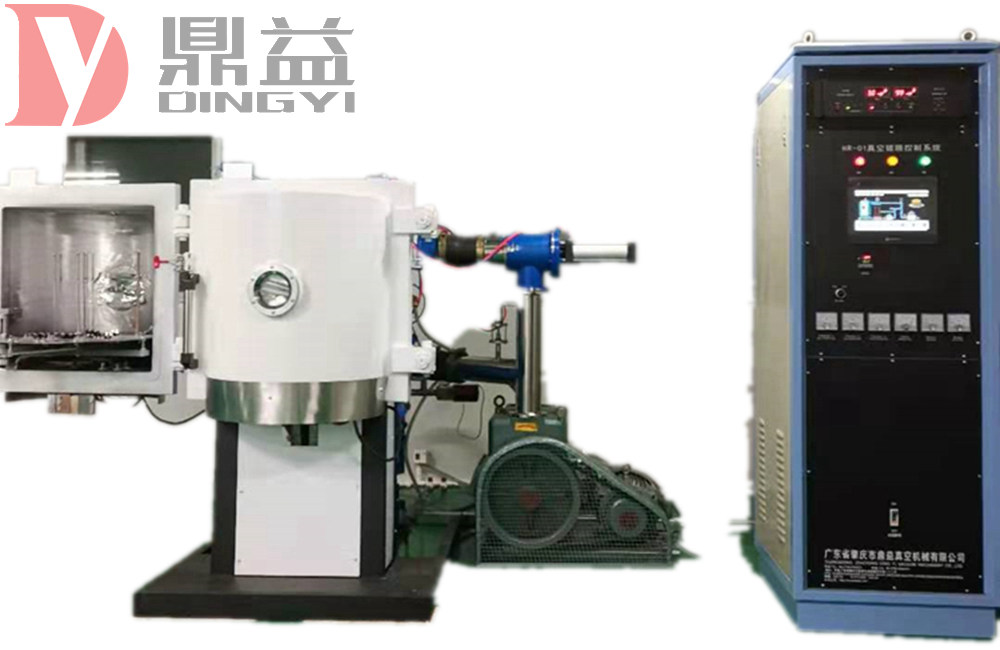

Laboratory coating equipment

300 meters southwest of Jindu Police Station, Century Avenue, Jindu Town, Gaoyao District, Zhaoqing City, Guangdong Province, China

+86 400-1133-638

+86 13925536251 (Mr. Deng)

380236471@qq.com

Copyright © 2022 Zhaoqing Dingyi Technology Co., Ltd