Server-Online

400-1133-638

13925536251

Thin film deposition technology is mainly divided into three major processes: physical, chemical and epitaxy according to the different film forming mechanisms. Physical vapor deposition coating equipment, referred to as PVD vacuum coating machine. Chemical vapor deposition coating machine, referred to as CVD coating machine.

Thin film deposition technology is an essential key process for the development of semiconductor, photovoltaic and other industries. Thin film deposition technology refers to the technology of depositing gas-phase atoms or molecules obtained by various methods under vacuum on the surface of the substrate material to obtain a release film. It is not only suitable for preparing superhard, corrosion-resistant, heat-resistant, and oxidation-resistant mechanical films, but also suitable for preparing functional films such as magnetic recording, information storage, photosensitive, heat-sensitive, superconducting, and photoelectric conversion; in addition, it can also be used for preparing Decorative coating. In the past 20 years, thin film deposition technology has developed rapidly and has been widely used in machinery, electronics, decoration and other fields.

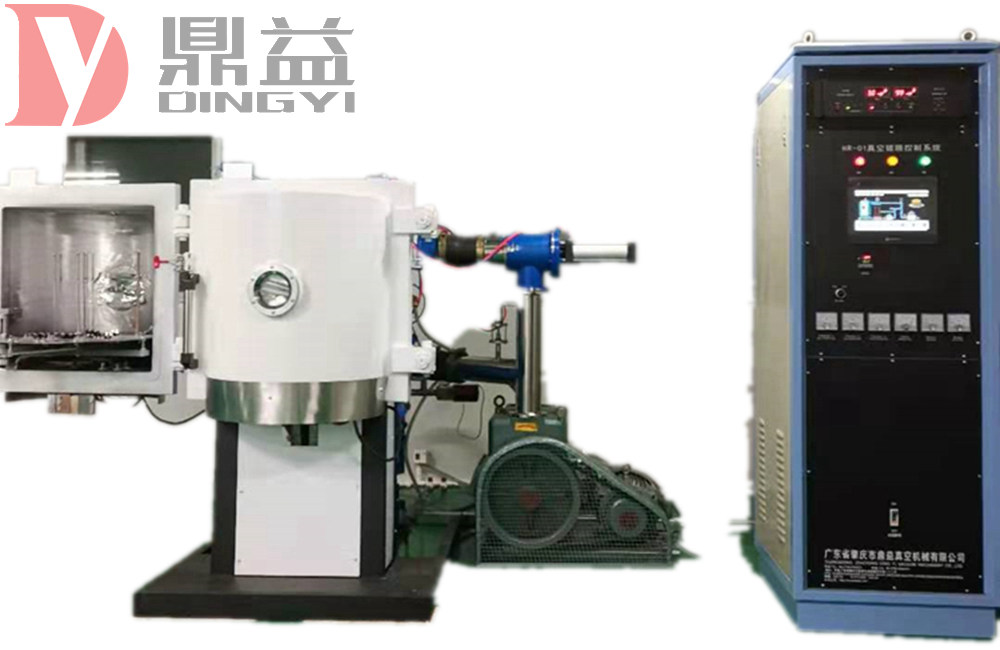

PVD vacuum coating machine has fast deposition speed, low deposition temperature, environmental friendly physical means, and is more suitable for the coating of hard alloy precision and complex tools. PVD refers to the use of physical methods such as high-temperature evaporation or high-energy particles to bombard the target under vacuum conditions, so that the surface atoms of the target "evaporate" and deposit on the substrate surface. The deposition rate is high, and it is generally applicable to various metals, non-metals, and compounds. Planar deposition of film layers. According to the difference in the physical mechanism of deposition, physical vapor deposition is generally divided into vacuum evaporation coating technology, vacuum sputtering coating, ion coating and molecular beam epitaxy. In recent years, the development of thin-film technology and thin-film materials has advanced by leaps and bounds and achieved remarkable results. On the basis of the original, ion beam enhanced deposition technology, electric spark deposition technology, electron beam physical vapor deposition technology and multi-layer spray deposition technology have appeared one after another.

There are many types of CVD coating equipment, and PECVD is currently the mainstream technology, and its market share is expected to further increase in the future. CVD refers to the process of using gaseous or vaporous substances to react on the gas phase or gas-solid interface to form solid deposits. It is a new technology for the preparation of inorganic materials developed in recent decades. Chemical vapor deposition has been widely used to purify substances, develop new crystals, and deposit various single crystal, polycrystalline or glassy inorganic thin film materials. These materials can be oxides, sulfides, nitrides, carbides, or binary or multi-element compounds in groups III-V, II-IV, and IV-VI, and their physical functions can be obtained through gas phase The dopant deposition process is precisely controlled. CVD coating has good repeatability and step coverage, and can be used for SiO2, Si3N4, PSG, BPSG, TEOS and other dielectric films, as well as semiconductor, metal (W), and various metal organic compound films. There are many types of CVD, which can be roughly divided into APCVD, LPCVD, SACVD, PECVD, MOCVD and other categories according to the chamber pressure and external energy. The reaction source of CVD equipment is easy to obtain, the coating composition is diverse, and the equipment is relatively simple. It is especially suitable for coating the surface and inner holes of parts with complex shapes.

Why does the evaporation coating machine coat under vacuum conditions

2023-03-11

Why does the evaporation coating machine coat under vacuum conditions

2023-03-11

If the pressure is not low enough (or the vacuum degree is not high enough), good results cannot be obtained. For example, if aluminum is deposited on the order of 10 2 Torr, the obtained film is not only not bright, but even gray and black. And the mechanical strength is extremely poor.

What is the difference between PVD vacuum coating machine and CVD coating machine?

2023-03-11

What is the difference between PVD vacuum coating machine and CVD coating machine?

2023-03-11

Thin film deposition technology is mainly divided into three major processes: physical, chemical, and epitaxy. Physical vapor deposition is referred to as PVD vacuum coating machine. Chemical vapor deposition is referred to as CVD coating machine for short.

Vacuum conditions in the process of vacuum evaporation coating machine

2023-03-03

Vacuum conditions in the process of vacuum evaporation coating machine

2023-03-03

In the vacuum chamber, when the particle concentration in the gas phase and the pressure of the residual gas are low enough, these particles can keep flying in a straight line from the evaporation source to the substrate, otherwise, they will collide and change the direction of motion.

Common problems of PVD evaporation process and sputtering process

2023-03-02

Common problems of PVD evaporation process and sputtering process

2023-03-02

Vacuum coating equipment uses two common coating processes, evaporation and sputtering. These two processes are currently the most popular and widely used, and their attention is naturally much higher than other processes.

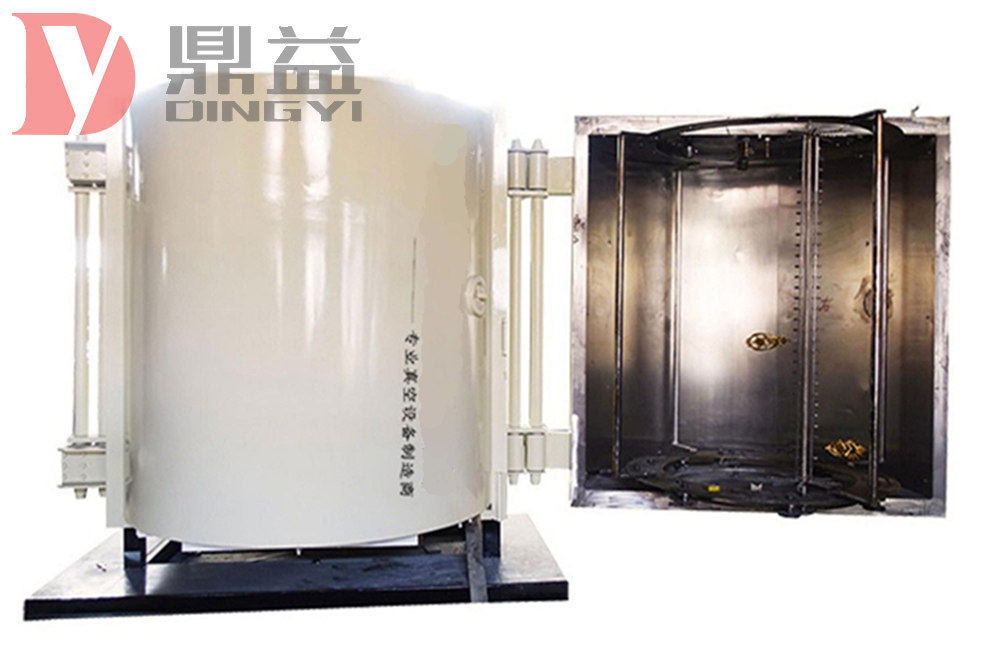

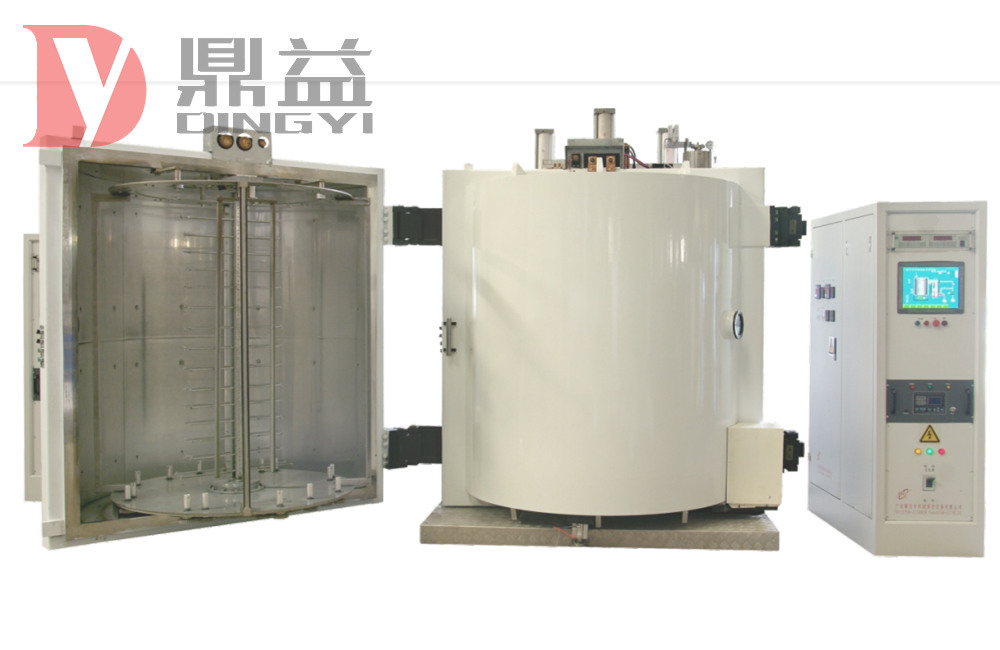

Vertical double-door-high vacuum evaporation coating machine

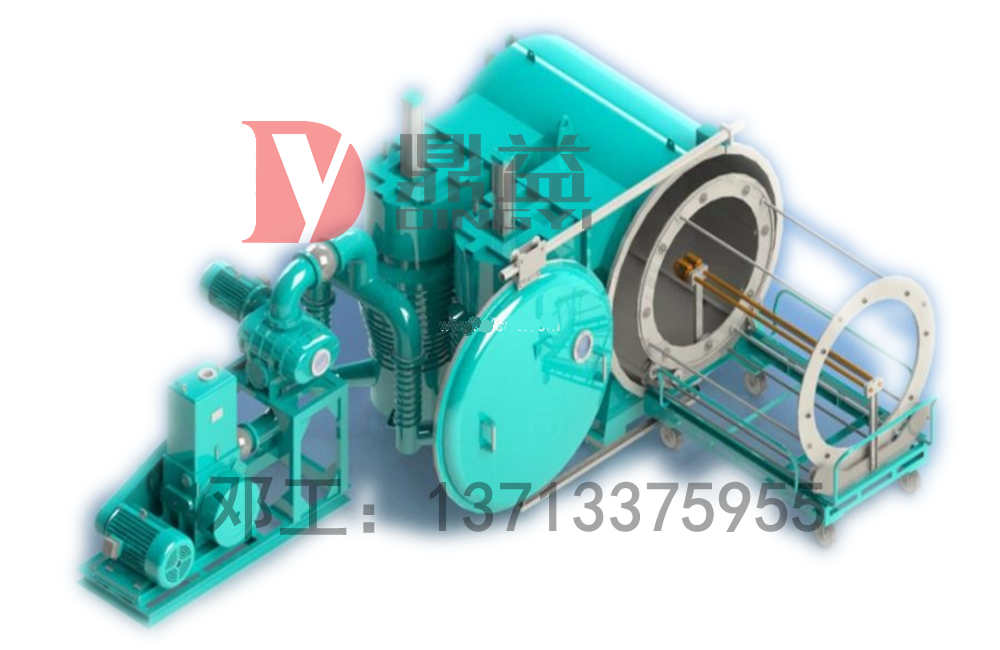

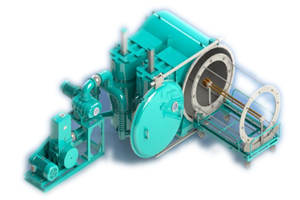

Horizontal evaporation coating machine

Vacuum coating machine for lamps

AF anti-fingerprint coating machine

PVD aluminum mirror coating machine

Vacuum internal plating equipment - evaporation coating machine - plastic/glass lampshade

Magnetic control evaporation dual-purpose coating machine

Laboratory coating equipment

300 meters southwest of Jindu Police Station, Century Avenue, Jindu Town, Gaoyao District, Zhaoqing City, Guangdong Province, China

+86 400-1133-638

+86 13925536251 (Mr. Deng)

380236471@qq.com

Copyright © 2022 Zhaoqing Dingyi Technology Co., Ltd